Economical Lift Maintenance Repair: Keeping Your Lifts Running Efficiently

Wiki Article

Pro Tips for Maintaining Your Lift in Top Problem: A Detailed Introduction

Ensuring the optimum performance of a lift system is crucial for a effective and risk-free procedure in various setups, from commercial storehouses to commercial structures. By sticking to a structured maintenance program and preemptively resolving potential issues, lift proprietors can mitigate costly downtime and safety risks.

Significance of Routine Upkeep

Regular maintenance of your lift is essential to ensure its ideal efficiency and durability. By adhering to a routine maintenance timetable, you can identify and resolve possible concerns prior to they rise into expensive repair work or unanticipated downtime. Routine upkeep jobs such as lubricating relocating components, evaluating for wear and tear, and inspecting hydraulic systems can aid prevent breakdowns and make sure risk-free procedure.Overlooking normal upkeep not only compromises the efficiency of your lift yet additionally presents security dangers to users and residential or commercial property. Elements that are not appropriately preserved might stop working suddenly, bring about accidents or damage to the lift itself. Moreover, resolving issues at an early stage with upkeep can extend the life-span of your lift and reduce the possibility of significant failures.

Along with improving security and performance, regular maintenance can likewise save you cash in the future. By purchasing preventative upkeep actions, you can avoid expensive repair work or substitutes that may emerge from disregarding the maintenance of your lift. On the whole, prioritizing routine maintenance is important for maximizing the performance and long life of your lift system.

Top Elements to Check

In addition, pay close attention to the lift's security features, such as emergency stop switches, security sensors, and interlocking systems, to guarantee they are operating correctly. Consistently inspect the lift shaft for particles or obstructions that can restrain the motion of the lift auto.

Proactive Repairing Techniques

By tracking metrics such as lift rate, motor temperature level, and energy usage, upkeep teams can recognize very early indicators of prospective concerns and take corrective actions before they escalate. In addition, applying a preventative maintenance schedule that consists of lubrication of moving parts, screening of emergency brakes, and calibration of sensing units can proactively resolve usual lift system issues.Furthermore, spending in training right here programs for upkeep personnel on repairing techniques specific to the lift design mounted can equip them to detect and solve problems quickly. By remaining ahead of prospective problems through proactive troubleshooting, lift drivers can make sure a smoother and much more dependable procedure while reducing the risk of unanticipated break downs.

Important Lubrication Practices

Executing appropriate lubrication methods is important for guaranteeing the smooth procedure and durability of lift systems. Normal lubrication helps lower friction between relocating components, avoiding deterioration that can bring about costly repair services and downtime. When it involves lift upkeep, complying with a stringent lubrication timetable is vital.Picking the ideal lubricant is the very first step in efficient upkeep. Different parts of the lift system might try these out need certain sorts of lubes, such as grease or oil. Seek advice from the supplier's standards to figure out the appropriate lubricants for each and every component.

Attend to any type of problems promptly to protect against additional damages and guarantee the ongoing smooth operation of your lift system. By focusing on appropriate lubrication practices, you can prolong the life expectancy of your lift and maximize its efficiency.

Precaution for Lift Operators

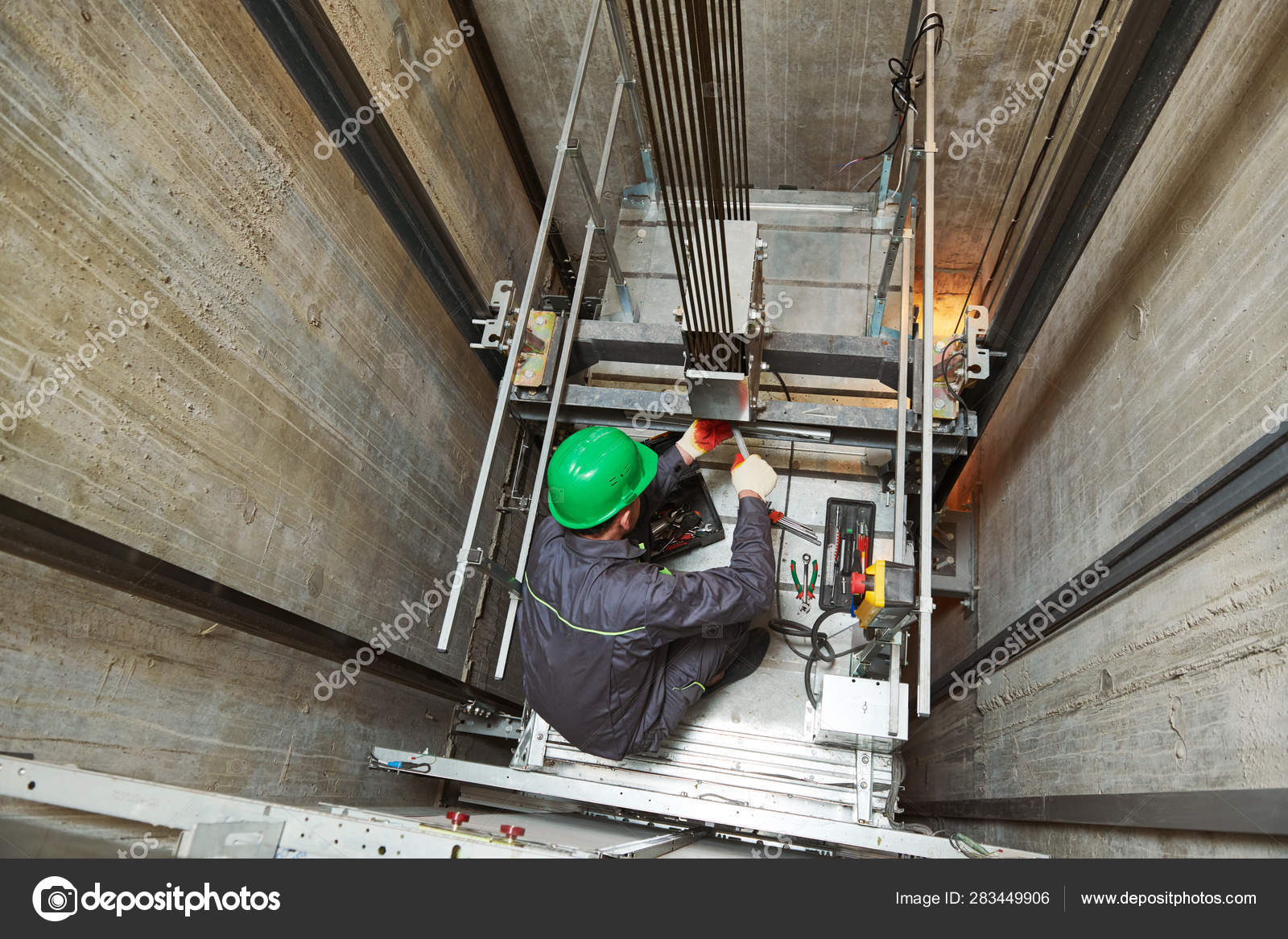

In order to keep a risk-free functioning atmosphere and support functional effectiveness, lift drivers need to carefully adhere to prescribed safety procedures, along with prioritizing essential lubrication techniques for ideal lift performance. Safety actions for lift operators are crucial to stop crashes and ensure the smooth functioning of the lift system. Operators must go through complete training on correct lift operation, emergency situation procedures, and safety standards. Normal tools assessments and upkeep checks are important to recognize and resolve any type of prospective safety threats promptly. It is necessary for operators to constantly adhere to supplier recommendations for tons capacities, functional limits, and security functions usage.Furthermore, lift drivers should focus on individual protective tools (PPE) such as helmets, gloves, and harness when functioning at elevations or imp source handling heavy lots. Clear communication among operators, maintenance professionals, and other employees is crucial to avoid misunderstandings that could bring about crashes. Finally, operators must remain attentive, focused, and stay clear of disturbances while operating the lift to make sure the security of themselves and others around.

Verdict

In final thought, preserving a lift in leading problem is vital for ensuring safety and efficiency in procedures. Routine maintenance, thorough examinations of essential parts, proactive troubleshooting, appropriate lubrication techniques, and adherence to safety actions are essential for extending the lifespan of the lift and avoiding crashes. By following these standards, lift drivers can ensure the ongoing performance and safety and security of their devices.By sticking to an organized maintenance regimen and preemptively attending to prospective problems, lift proprietors can mitigate costly downtime and safety hazards. Routinely check the lift shaft for debris or obstructions that might hinder the movement of the lift auto.In order to maintain a safe functioning environment and maintain operational performance, lift drivers need to carefully adhere to suggested safety and security methods, alongside focusing on vital lubrication methods for ideal lift efficiency. Security actions for lift drivers are critical to avoid accidents and ensure the smooth performance of the lift system. Regular upkeep, thorough examinations of vital elements, aggressive troubleshooting, correct lubrication methods, and adherence to security procedures are necessary for lengthening the life-span of the lift and protecting against accidents.

Report this wiki page